Design a metal lamp that it is beautiful in form & celebrates light’s beauty when lit.

My two goals in the completion of this project were, firstly, to explore the material properties of aluminum and concrete through my design & to create a functional lamp that could be used in a home. Secondly, I aimed to distill what makes light “beautiful” into criteria that would inform the final design.

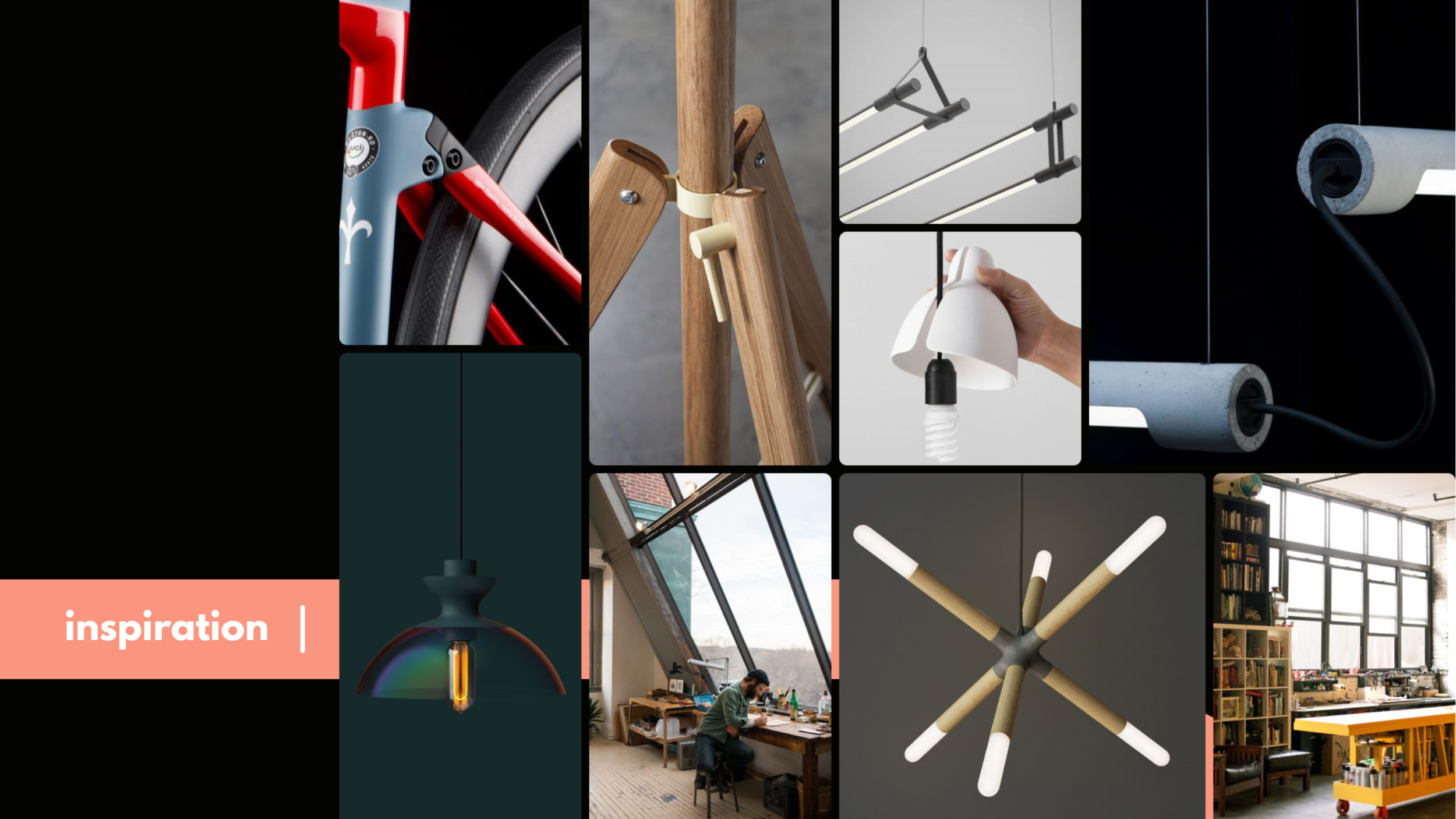

Contrast, Motion, & Emotion make light beautiful.

contrast.

Light needs darkness to fully shine. Without contrast, light fades into the backdrop, calling attention to the illuminated, not the illumination.

emotion.

We know that light temperature & intensity can create certain emotions or moods for the user. How can that be leveraged?

motion.

Part of the beauty of light is how in motion it is at all times. A lamp that celebrates the beauty of light should celebrate its motion.

early sketches.

manufacturing.

Due to the complex shape of the center hub of my lamp design, I chose to 3D print a mold to cast concrete into the correct shape. This was my first experiment with concrete & 3d printing molds, so some iteration was needed!

hub mold v1.

V1 Problems.

2 piece design is difficult to remove & chips the part’s edges.

Weak mounting points. One broke after just one test, not durable enough for final.

Concrete leaks through the parting line, 2 clamping points aren’t providing enough force.

hub mold v2.

V2 solutions/improvements.

3 piece construction & the addition of Vaseline to the mold makes removing the hub a smooth operation!

Increased the thickness and filet radii of all clamping surfaces.

6 clamping points instead of 2. Also, I added feet to increase stability & ensure the mold sits flat.

The Lamp fixtures are made out of Aluminum tubing cut to length & milled then band-sawed into the correct profile.

I connected the fixtures to the hub by using epoxy to mount steel inserts inside the tubes. The bolts sticking out of the end thread into the threaded inserts molded into the concrete hub. Electrical cords feed through the slot in the steel inserts & out the hole on the top of the fixture tubes.

final design.